Materials

Plastics as base materials

About our materials

Foam gives designers great flexibility to use special and distinctive shapes. Designs that can be realised easily and economically. IFG gladly advises you on all possibilities and options regarding the use and applications of foam.

The basic materials that IFG uses are synthetic materials. This means that they are manufactured via an industrial chemical process. They are so-called ‘polymers’. A polymer is a substance that consists of molecules linked together in a sequence of several identical parts.

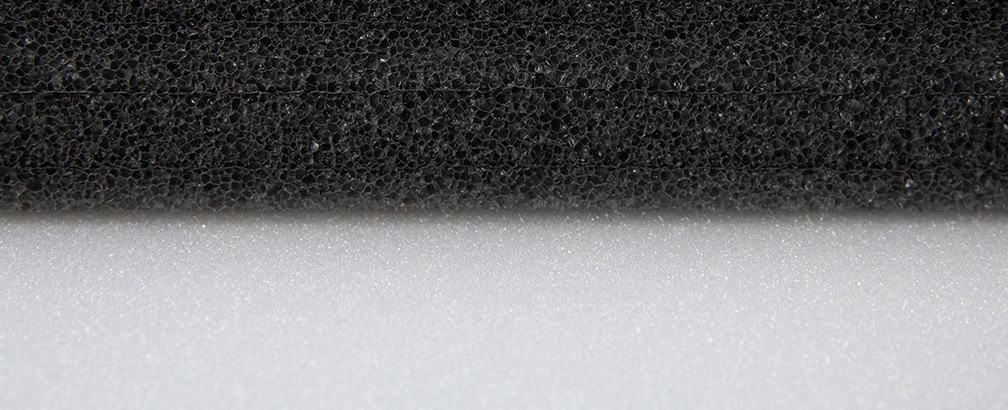

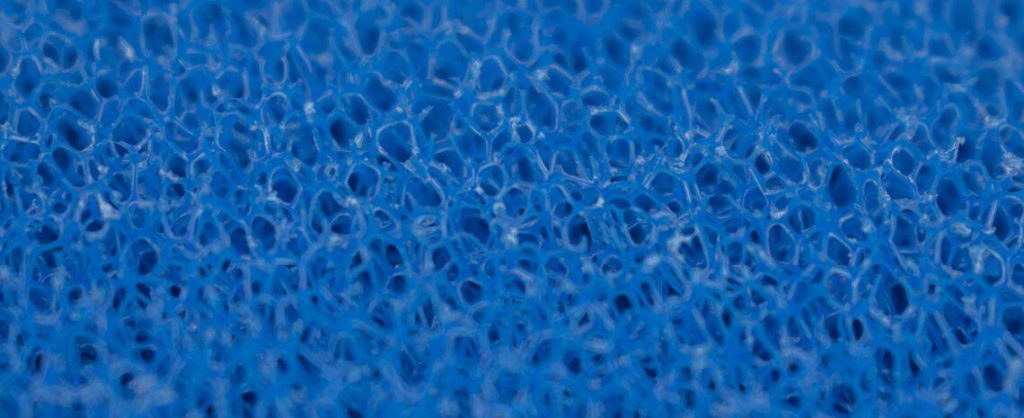

Foam is created by creating gas pockets during the production of the polymer. The pockets of gas can be closed or open (open-cell or closed-cell foam). This structure obviously has an effect on the technical properties of the foam.

The structure of the gas pockets determines, among other things, the weight, resilience and strength of the foam. By combining and varying, these foam properties can be expanded in various ways.

For example, there are crosslinked and non-crosslinked types of foam. In the first variant, the molecules of the foam are linked together to form a three-dimensional network. The second variant does not. This leads to unique properties.

Polyethylene (PE)

The most commonly used plastic. Polyethylene is a closed-cell foam and is made by polymerising ethylene. Ethylene is obtained by breaking down (cracking) naphtha, a light derivative of petroleum, among other things.

Polyurethane (PU)

An important family of polymers with many applications. For example, it is used as insulation in construction, for furniture in office environments or in refrigerators and freezers. PU is a copolymer that consists of two segments: a hard and a soft component.

Polyurea (coating)

A two-component polymer (Isocyanate and Polymer resin) with a high molecular density. After a brief exothermic reaction, a very tough and extremely elastic uniform protective layer is created, which is very suitable for use as a coating.